Grilling a lamb

Posted on

The other week we grilled a whole lamb that we bought from a farmer. On the whole it went okay with some ups and downs. Once it was settled that we were going to do it I had the idea to make some kind of contraption that could spin the animal on a stick for us, thinking that it would save us some time if we could just "set it and forget it".

The basic idea was to use an old bike as the thing that the lamb would be attached to, and then spin the back wheel backwards, leading to the pedals rotating, which in turn would turn the lamb. Since the back wheel would be driven by a motor the motor shouldn't need to be as strong as if it would turn the animal directly, due to the gear ratios.

In my naivity, I first tried with the motor for a computer chassis fan. I 3d- printed a small holder which allowed me to attach a stick to the middle of the spinning fan. The stick was then pressed against the wheel in an attempt to get it to spin. Needless to say, this wouldn't move the wheel at all, the motor just instantly stopped. I could've experimented with removing the fan blades, but it seemed quite obvious that it wouldn't work anyway.

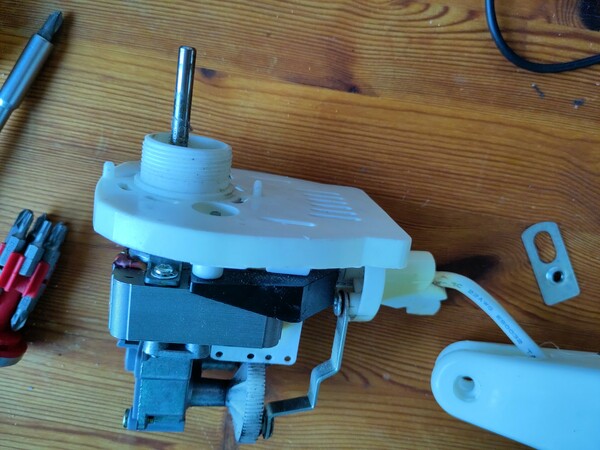

After looking for a bit I found our trusty old desk fan which has seen better days. I removed the fan from it and kept the motor, this seemed to be able to move the wheel of the bike. Here's the motor minus fan:

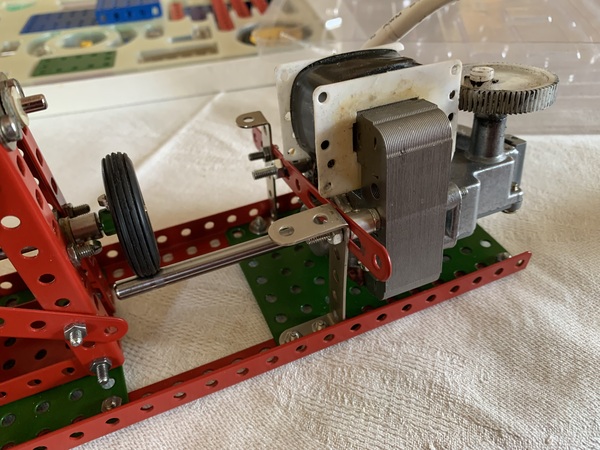

I was thinking of mounting this directly to the wheel, but this seemed like it would spin the wheel too fast, so some kind of gear exchange was probably needed. Time was a bit tight now and my parents had offered to help. They created this masterpiece which seemed to have a chance of working:

Up until this point i had just assumed that the weight distribution around the stick would be pretty even. Unfortunately (and probably obviously in hindsight) this was not the case. Along with that issue the animal weighed quite a lot (around 20 kg) and this weight hung directly on the driving axle of the bike. These 2 factors combined lead to the motor not really being able to turn the animal at all, so in the end we had to spin it by hand. Anyway, we had a great time!

Lessons

Til' next time it's probably a good idea to create some kind of weight relief, letting most of the weight of the animal be on some kind of support/s, so that there's less friction when trying to turn the rod that the animal is on.

The iron rod i initially wanted to put the animal on was waaaaay to weak, it was just 10mm in diameter and that was not enough. 20mm is probably a minimum for this kind of weight. We ended up using a somewhat thick branch in conjunction with the iron rod to support the animals weight.

Somehow attaching the rod from the motor to the gear box with something other than friction would also be good, the final construction was dependent on two different axels pressing on each other just right. It would be better to either weld them together somehow or let them be connected via gears.